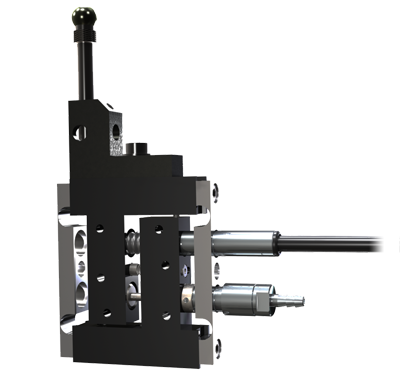

Flexures block gauge "AU" and "DU"

Flexures block gauge "AU" and "DU"

Flexure block gauge is ideal for very high volume and high precision applications such as bearing components gauging. It is often the best solution for measuring moving materials, such as roughness testing.

AU : With inductive probe

DU : With digital probe

Flexure block gauge is ideal for very high volume and high precision applications such as bearing components gauging. It is often the best solution for measuring moving materials, such as roughness testing. There are no sliding parts to wear out or to cause friction within the frame or sensor whoch makes Metro flexures virtually free from hysteresis.

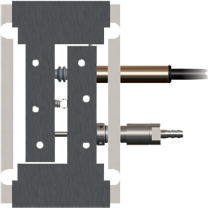

Flexures can be mounted such that there is little or no stress through the gauge centre line and enabling precision profiling of moving material, such as sheet material or rotating shafts, brake discs etc.The flexure gauge has forward and reverse spring action with a pneumatically actuated version available for automatic measurements

- Measuring range : ±0.5 et ±10 mm

- Repeatability : < 0,1 µm

- Inductive or digital probe

- High precision measurement

- SPring push or pneumatic actuation

- IP Rate : IP65

- Aluminium and stainless steel construction

- Wide range of contact tips

- Extended operation life > 20 million cycles

| AU / 0.5 | AU / 1.0 | |

|---|---|---|

| Mechanical travel (mm) | 1.7 | 2.5 |

| Measuring range (mm) | 1.0 | 2.0 |

| Precision | 0.1 | 0.1 |

| Repeatability | < 0.1 µm | < 0.1 µm |

| Tip force, spring push | 1.5N à mi course | 1.5N à mi course |

| Tip force, pneumatic | 1N à mi course @ 2 bar | 1N à mi course @ 2 bar |

| Temperature coefficient | < 0,01 % from full scale by °C | < 0,01 % from full scale by °C |

| Mass (including tool holder, 20mm tip holder and ball tip exluding PIE/cable) | < 60g | < 70g |

| Mass tool holdert | 12g | 12g |

| Materials | Aluminium and stainless steel | Aluminium and stainless steel |

| Pneumatic operation pressure | 1.5 Bar to 2.5 Bar | 1.5 Bar to 2.5 Bar |

| Operating temperature | 5°C à +85°C | 5°C à +85°C |

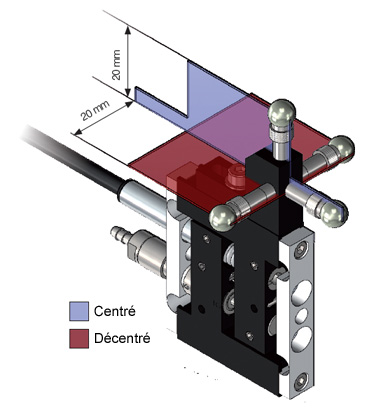

For optimal gauging performance the recommended operation is on centre. The specification is valid when using Metro standard tool holder, tip holder and tip. (Tip used is 6.35 mm TC Ball Tip)

- Repeatability on centre : < 0.1µm

- Repeatability off centre : < 0.5µm

The gauge is supplied inclusive of sensor but does not include the tool holder, tip carrier or tips. There are versions for spring push and pneumatic push with axial and radial cable exit. Accessories are common to both AU/0.5 and AU/1 versions.

|

Tips

|

Industrial standard tips (Thread M 2,5)

|

||||||

|

|

|||||||

|

Tip holder

|

Lenght

|

Tip holder

|

|||||

|

20 mm

|

Ref 208221/20

|

||||||

|

30 mm

|

Ref 208221/30

|

||||||

|

40 mm

|

Ref 208221/40

|

||||||

|

|

|||||||

|

Tool holder

|

ref 806274

|

||||||

|

|

|||||||

|

Analogue or digital module

|

|||||||

|

Stroke 1 mm

|

Stroke 2 mm

|

||||||

|

Type of product

|

Analogue

|

Digital

|

Analogue

|

Digital

|

|||

|

Axial output

|

+- 0.5mm

|

+-1.0mm

|

|||||

|

Forward spring

|

AU/0.5/SH

|

DU/1/S

|

AU/1.0/SH

|

DU/2/S

|

|||

|

Reverse spring

|

AU/0.5/RH

|

DU/1/R

|

AU/1.0/RH

|

DU/2/R

|

|||

|

Reverse spring pneumatic

|

AU/0.5/PH

|

DU/1/P

|

AU/1.0/PH

|

DU/2/P

|

|||

|

Radial output

|

+-0.5mm

|

+-1.0mm

|

|||||

|

Forward spring

|

AUR/0.5/SH

|

DUR/1/S

|

AUR/1.0/SH

|

DUR/2/S

|

|||

|

Reverse spring

|

AUR/0.5/RH

|

DUR/1/R

|

AUR/1.0/RH

|

DUR/2/R

|

|||

|

Reverse spring pneumatic

|

AUR/0.5/PH

|

DUR/1/P

|

AUR/1.0/PH

|

DUR/2/P

|

|||