Discover our solutions in the field of ball bearings

Ball bearings are all around us. In cars, planes, wind turbines, everyday objects;

Ball bearings are precision parts that require precise and reliable control. Metro products are perfectly suited to this mission and we are present with the main players in the field.

METRO product applications in the field of ball bearings

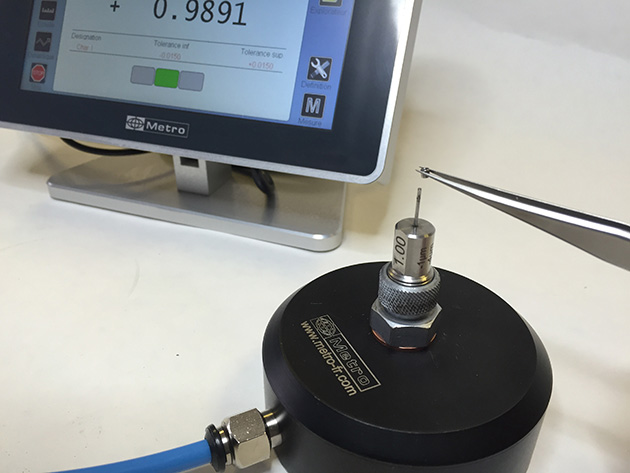

The pneumatic measurement technique (air gage) is often used for diameter measurements on ball bearing components because of the high precision offered by this method and the absence of contact avoiding potential scratches.

The example opposite shows a manual measurement of an inside diameter of 1mm with a tolerance interval of 3µm.

The pneumatic measurement technic (air gage) is often used for diameter measurements on ball bearing components because of the high precision offered by this method and the absence of contact avoiding potential scratches.

Also, the low pressure applied by the air does not deform the thin inner ring, which is the case in this example.

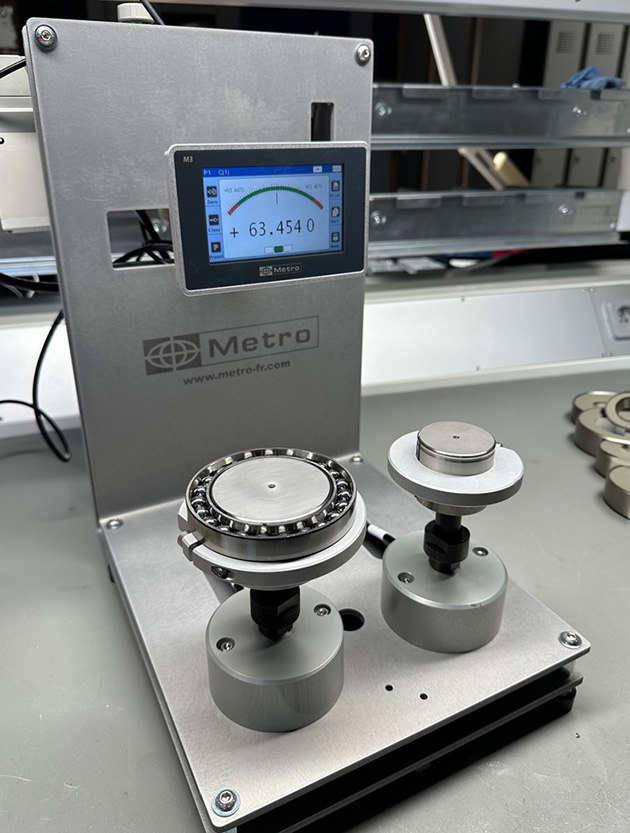

The example opposite shows a manual measuring station capable of measuring 2 different diameters. This station is fitted with the Metro air-saving system, which enables considerable savings to be made on the electricity consumed by the air at this station, without affecting accuracy.

This example is a retrofit of an Etamic station where we have kept the airg plugs. Metro displays are compatible with all manufacturers of air gages.