Discover our product lines

Our precision measuring devices for dimensional metrology

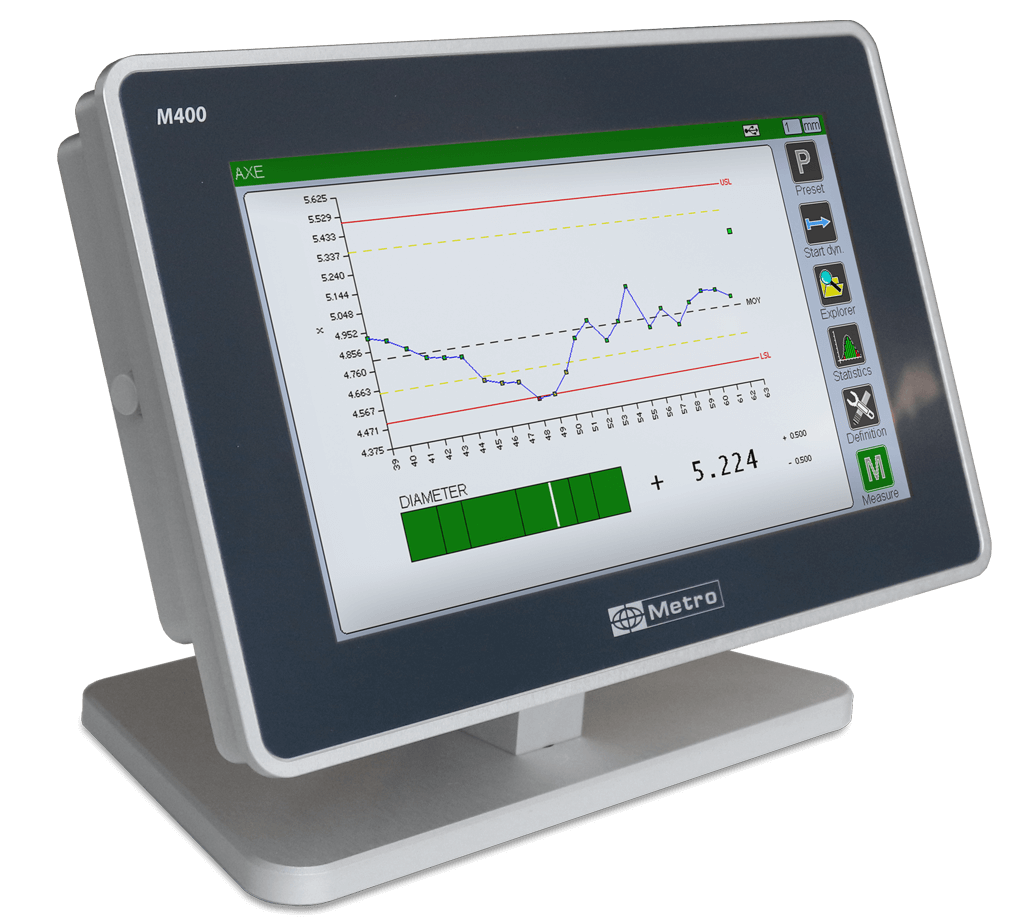

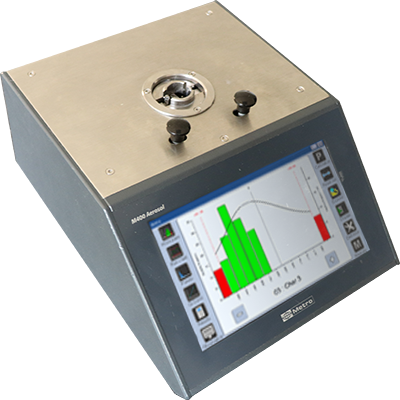

All METRO electronic dimensional metrology devices

Metro offers complete precision measurement solutions for metrology. Metro develops and produces a varied and high-performance range of displays, multiplexers and probes to meet all your dimensional measurement needs. Discover our products….

See all products

Search products & filters

so you don't miss anything

Subscribe to our newsletter