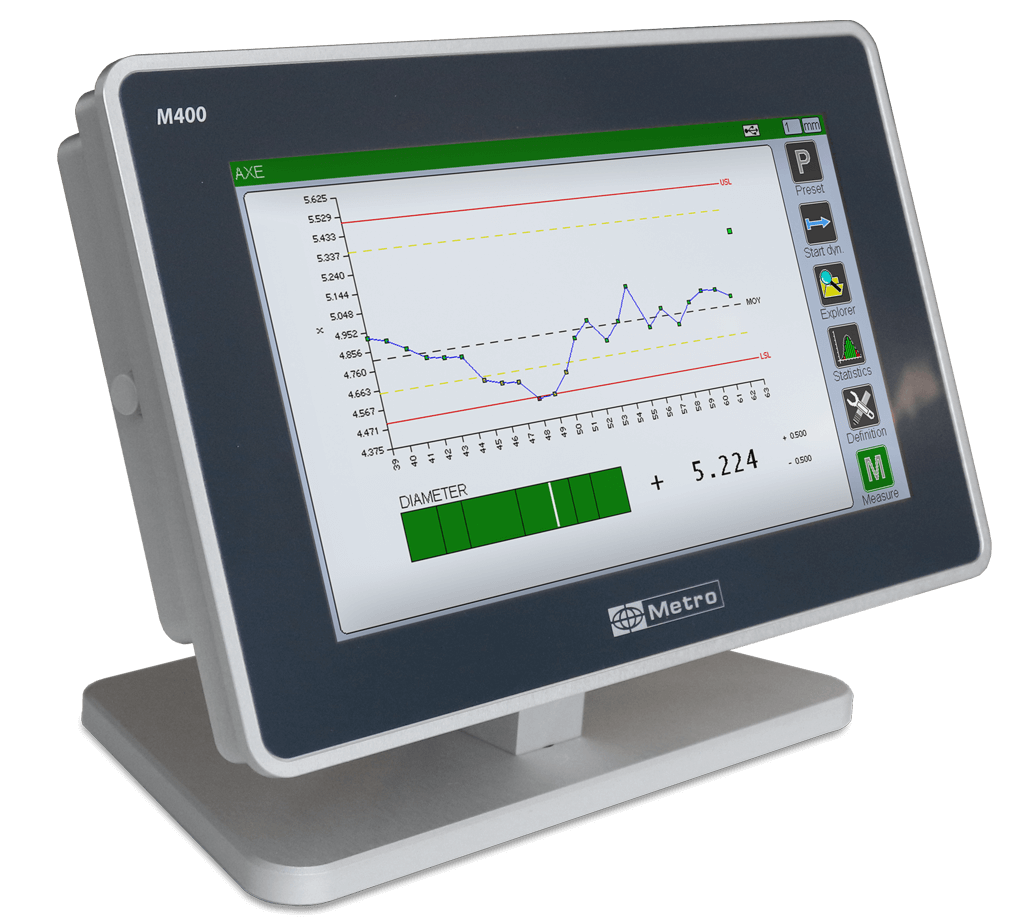

M400 - Digital readout for gauging probes

M400 - Digital readout for gauging probes

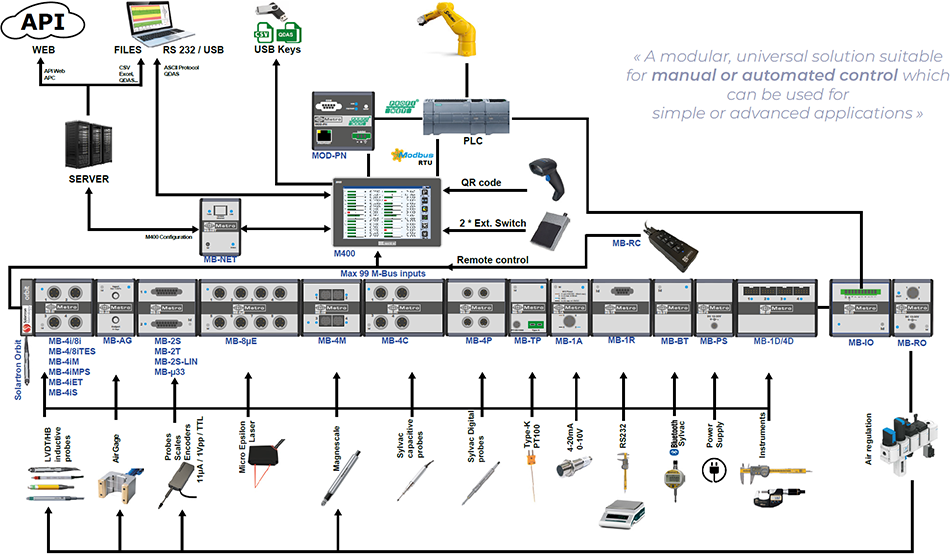

The M400 is universal (different probe's technologies accepted) and powerful (up to 32 characteristics displayed in the same time, trigonometrical functions, statistical functions, PLC functions...)

The M400 is able to communicate with PLC using modbus RTU or Profinet (through our Certified Profinet MOD-PN module).

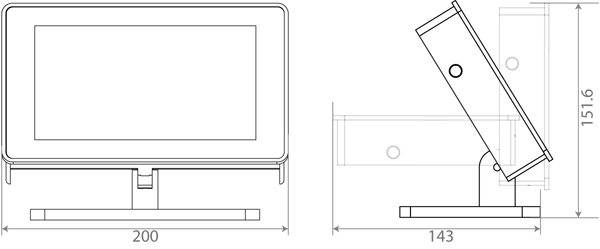

Thanks to its intuitive menus and its general simplicity the M400 is a device that will be immediately adopted by every operator. Its housing machined in a solid aluminium block offers to the M400 an incomparable robustness, even used in the most severe industrial environments.

The M400 front face is covered by an integral polyester sheet that ensures a protection against liquid projections like oil. The M400 can either be delivered as a table device or for panel mounting.

- Up to 99 inputs : Air gages, Inductive (Metro, Tesa, Mahr, Marposs, Solartron Ametek etc) or digital probes (Orbit), incremental encoders (Heidenhain, Magnescale, Mitutoyo) or capacitives (Sylvac), temperature, I/O etc..

- Possibility to display measurements from instruments (calipers, dial gauges etc.) from any brand but also to interface bigger measuring tools like roughness testers or laser micrometers.

- Compatible with the Sylvac and Bowers bluetooth instruments

- Up to 32 characteristics displayed in the same screen

- Several measuring modes : continous, cyclic or sequential through a very simple interface ( similar as a simplified grafcet)

- SPC functions

- Network connexion through the MB-NET module : creation of measuring files on your network like : CSV, DFQ (QDAS etc), XLS, PDF and other on demand.

- Various means of communications and connections facilities : Profinet (via the MOD-PN external module) USB Host and device, Modbus RTU, RS232, Footswitch...

- Very easy to use and reliable

- Can be used a a PLC for simple and semi-automated application thanks to a simplified visual basic script.

Do you need to save your measurements on your network? The M400 can be delivered with a network acquisition solution allowing both to generate customizable measurement files (CSV, XLSX or other) but also to configure the M400 remotely. This is possible thanks to the use of the MB-NET module and the Metro Data Server software.

The M400 digital readout is fitted with a 7’’ colour display with the touch screen functions allowing an easy configuration of the device thanks to its icon desktop, its windows and its drop down menus. Measurement is displayed with bargraphs, up the 32 measurement characteristics simultaneously.

Virtual keyboards (alphanumerical, numerical and with trigonometrical functions) allows entering part’s names, calculation formulas... An automatic system checks if data is entered with the right format and prevent any typing error.

The M400 is running on our own operating system (not on Windows CE or similar), this allows high performances of display in terms of probe’s reading rate for example. The size of the measurement barmeters adapts depending on the characteristics numbers (up to 32).

One advantage of the M400 is its compatibility with different technologies of probes Probes are connected on separate modules through the M-bus network. This modular configuration offers the following advantages :

- Flexibility of the probes number (up to 99)

- Possibility to use simultaneously different technologies of probes :

- Inductive (Metro, Tesa compatible, etc...)

- Incremental linear encoders (Metro, Heindenhain, Magnescale, Mitutoyo)

- Capacitive (Sylvac)

- Digital (Metro - Solartron Orbit)

- The M400 display unit can be installed far from the probes. Extension modules are connected by only one cable to the M400 without any risk of signal deterioration.

The M400 is able to store up to 1'000 measurements by part reference and up to 128 part references can be memorized.

The data collected can then be used localy on the M400 for SPC analysis. The following functions are for example available.

The MB-IO module enables to interface automatism devices to the M400 thanks to its 8 optocoupled I/O.

A simple programmation language allows then to define the needed actions in functions of the inputs and the internal status of the M400. Thanks to this language the user can define an PLC program included in the control characteristics in order to perform the requested functions. These remote I/O are made to automate the measurements. They bring the following additionnal functionnalities :

- Direct automation of a machine by the M400

- Automation of the measurement by an external system (PLC)

- Transmission or display of messages on the screen in function of programmable events.

The M400 is not fitted with direct probes inputs. It is necessary to use our M-Bus probes conditionners to connect probes to the M400.

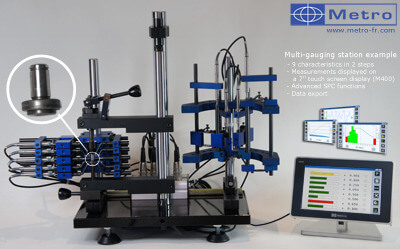

Use on multi-dimensional fixtures.

Many industries of precision mechanics use multi-dimensional assemblies with comparators. A M400+inductive sensors solution replaces advantageously the comparators in such assemblies.

Indeed, the reading of each comparator, then the recording of the results is long and source of errors.

By using the same mechanical assembly, the M400 makes it possible to take all the measurements simultaneously (up to 32), to display very clearly the position of each measurement compared to its tolerances as well as the result good part / bad part. At the same time, the M400 can send the measurement results to a PC or a PLC and display locally numerous statistical screens.

The productivity of the operator is increased tenfold and the risk of error becomes almost zero, the return on investment is immediate.

Watch industry

The manufacture of mechanical watches requires an impeccable measurement quality. Sensors must have a high accuracy over their entire measuring range in order to measure parts of different sizes with the same sensor. Sylvac or Heidenhain sensors are therefore very well suited to this mission. With the M400, the dimensions of these sensors can be displayed with great clarity. Thanks to the galvanometer display mode and the automatic change of dimension by sensor movement, the M400 is a device which will facilitate the work of the control operator. The measurements can be sent to a PC or processed locally with statistical functions to ensure a high quality monitoring. The M400 is a compact device despite the size of its screen (7'', 17.6cm) which is often an important point on a workstation.

Measurement of 4 diameters simultaneously with a small tolerance by air gage

This sturdy pedal can be configured in different ways: calibration, measurement transmission, start of dynamic measurement etc...

This robust and ergonomic button is made on a machined aluminum base.

It advantageously replaces the pedal when it is used on a table.

Compatible with all Metro products: Displays and multiplexers.

The MB-IO M-Bus box has 8 optocoupled inputs/outputs for additional functionality, e.g. output of good or bad parts, calibration input etc. The M-Bus units are presented in an aluminum profile that can be mounted on a standard DIN rail. More details on this page: M-BUS