Block gauge BG

Block gauge BG

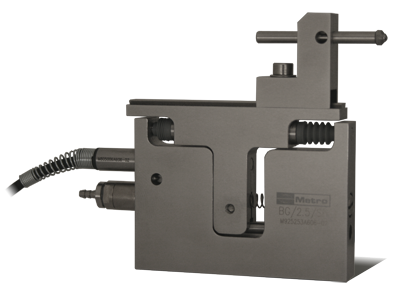

The block gauge BG enables to make simple and reliable measurements. It is particularly adapted to control bores or more generally where it is difficult to use a standard pencil probe. The motion is ensured by precision linear bearings that ensure an excellent repeatability.

The Measuring Module allows simple and precise measurements. It is ideal for checking diameters or more generally dimensions that are difficult to access with a conventional probe.

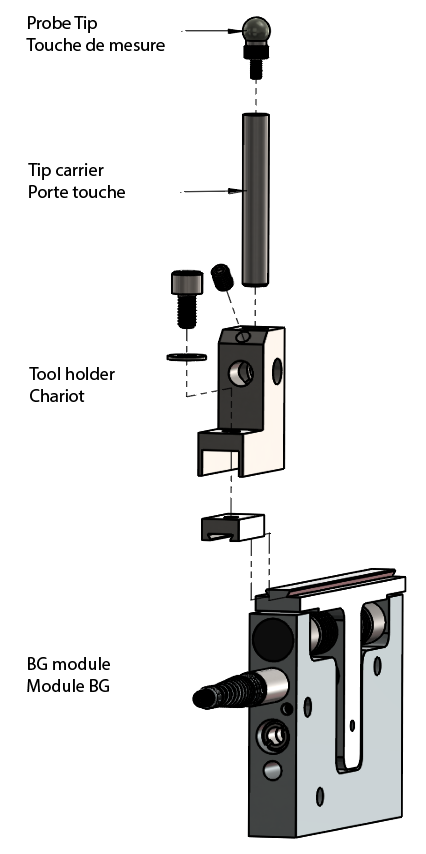

The probe holder is adjustable to meet the requirements of different industrial applications. This holder accepts all touch probes with M2.5 threads.

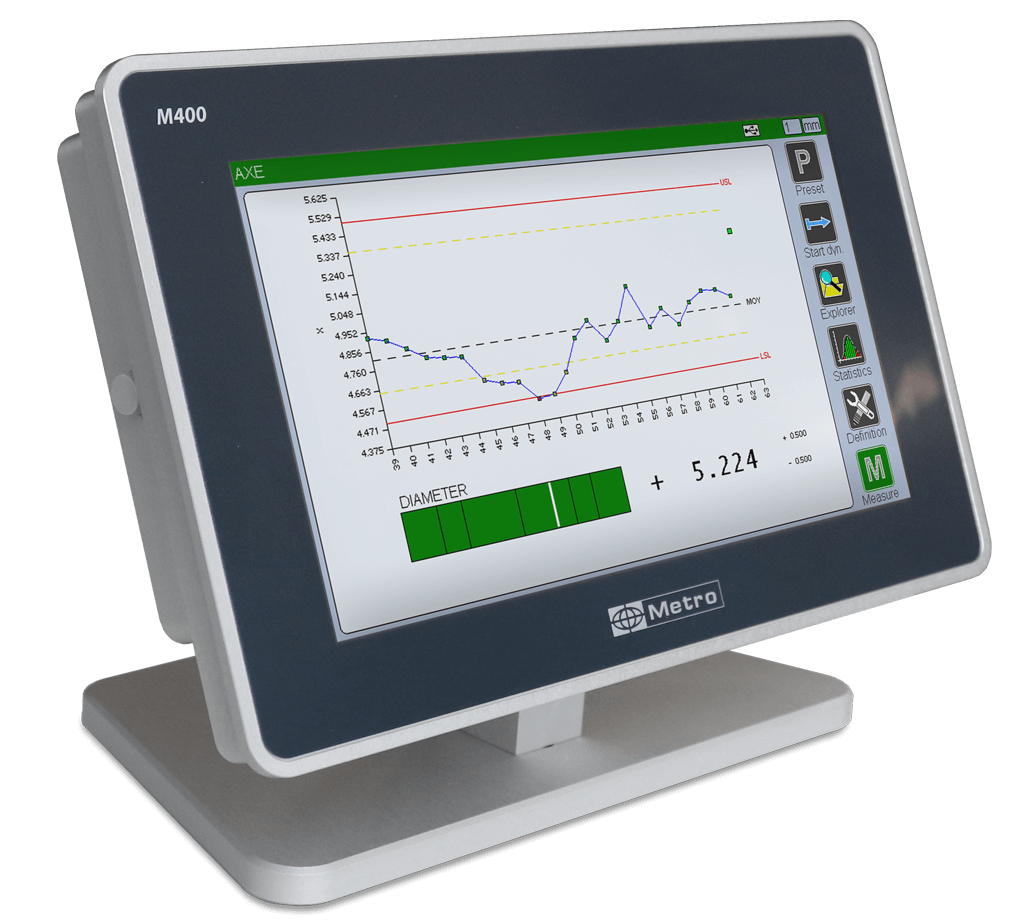

The digital and analog versions of the Measuring Module offer high performance in terms of accuracy, resolution and repeatability.

The range of control interfaces has 2mm, 5mm and 10mm strokes. The 5 mm Module is used in most control applications and the 10 mm Module covers applications that require more travel. The 2 mm Module is a miniaturized version in length, weight and thickness. It is recommended when space is at a premium.

| With inductive sensor | With digital sensor | |

|---|---|---|

| Mechanical stroke | 3, 6, 11 mm | 3, 6, 11 mm |

| Measuring range | ±1, ±2.5, ±5 mm | 2, 5, 10 mm |

| Accuracy | ||

| - 2 mm | ±1 µm ou ±0,5 %x D | ±1 µm ±0,1 %x D |

| - 5 mm | ±2,5 µm ou ±0,5 %x D | ±1 µm ±0,15 %x D |

| - 10 mm | ±5 µm ou ±0,5 %x D | ±1 µm ±0,15 %x D |

| Repeatability | < 0.25 µm | < 0.25 µm |

| Zero-electricity | Adjustable on the stroke | Not applicable |

| Supporting force | Adjustable from 0.5N to 1N | Adjustable from 0.5N to 1N |

| Temperature drift | < 0.01% of full scale per °C | < 0.01% of full scale per °C |

| Weight (excluding cart) | 2mm = 160 g ; 5 mm = 390 g ; 10 mm = 385 g | 2mm = 160 g ; 5 mm = 390 g ; 10 mm = 385 g |

| Mass of the sliding part (without carriage) | 2mm = 35 g ; 5 mm = 90 g ; 10 mm = 95 g | 2mm = 35 g ; 5 mm = 90 g ; 10 mm = 95 g |

| Carriage weight | 25g | 25g |

| Materials | Stainless steel and Viton bellows | Stainless steel and Viton bellows |

| Permissible pressure | 1 Bar à 7 Bar | 1 Bar à 7 Bar |

| Operating temperature | 10°C à +85°C | 10°C à +60°C |

On the standard version, the block gauge is actuated by spring. The pneumatic actuation option requires to use an actuator (article reference 804570-SX). The block gauge does not include the holder, the tip holder and the probe tip that must be orderd separately. A kit including several springs (in order to adjust the tip force) is delivered together with the block gauge. It is also possible to be delivered separatly. (article reference 208212-SX).

|

Probe tips

|

Industrial standard probes tip (M 2,5)

|

||||||

|

|

|||||||

|

Tip carrier

|

Length

|

Tip carrier Ø 4 mm

|

Tip carrier Ø 6 mm

|

||||

|

20 mm

|

83420

|

-------

|

|||||

|

30 mm

|

83430

|

83630

|

|||||

|

40 mm

|

83440

|

83640

|

|||||

|

50 mm

|

-------

|

83650

|

|||||

|

|

|||||||

|

Tool holder

|

Block gauge

|

4mm Tool holder

Article ref

|

6mm Tool holder

Article ref

|

||||

|

2 mm

|

83401

|

-------

|

|||||

|

5 & 10 mm

|

83402

|

83602

|

|||||

|

|

|||||||

|

Inductive or digital block gauge

|

|||||||

|

Stroke 2 mm

|

Stroke 5 mm

|

Stroke 10 mm

|

|||||

|

Inductive

|

Ref.

|

Code

|

Ref.

|

Code

|

Ref.

|

Code

|

|

|

Axial output

|

BG/1

|

80201-2

|

BG/2.5

|

80201-5

|

BG/5

|

80201-10

|

|

|

Radial output

|

-------

|

-------

|

BGR/2.5

|

80201-5R

|

BG/5R

|

80201-10R

|

|

|

Digital

|

Ref.

|

Code

|

Ref.

|

Code

|

Ref.

|

Code

|

|

|

Axial output

|

DK/2/S

|

81201-2

|

DK/5/S

|

81201-5

|

DK/10/S

|

81201-10

|

|

|

Radial output

|

-------

|

-------

|

DKR/5/S

|

81201-5R

|

DKR/10/S

|

81201-10R

|

|

|

|

|||||||

|

Pneumatic actuator

|

Block size

|

Article ref

|

|||||

|

2 mm

|

83403

|

||||||

|

5 & 10 mm

|

83404

|

||||||

|

Replacement string

|

2 mm module

|

5 mm module

|

10 mm module

|

||||

|

70 g

|

832070

|

-------

|

-------

|

||||

|

75 g

|

-------

|

835075

|

831075

|

||||

|

100 g

|

832100

|

835100

|

831100

|

||||

|

150 g

|

832150

|

835150

|

831150

|

||||

|

250 g

|

-------

|

835250

|

831250

|

||||

|

350 g

|

-------

|

835350

|

831350

|

||||

The pneumatic kit allows automated controls. Used with a spring it offers the possibility to adjust the tip force keeping a excellent repeatability.

The mechanical interface that hold the probe tip is perfectly rigid but allows an easy adjustment. The tip carrier accepts all the probe tips having a M2.5 screw thread.

Several block gauges can be mounted together. This very compact configuration enables controls where space is limited. It enables also to off-center the blocks (fig3).

The block gauge thank sto its adjustable toll carrier enable to realize measurements at a distance >40mm (fig4).

A wide range of spring enables to use the block gauge in every directions.

With a IP 65 rating, the block gauge is usable in the most severe industrial environments. (fig5).