Display unit M1-M3 Air Gages

Display unit M1-M3 Air Gages

The M3 is the last generation of tool for dimensional control with an air gage : air ring, air plug gage, air fork etc.

The M3 is compatible with all the air gage brands available making possible to keep your current air gage and to use this modern and versatile display.

The M3 AG is a new generation of electronic for air gages

Thanks to its intuitive interface and its simplicity, the M3 will be immediately adopted by all operators.

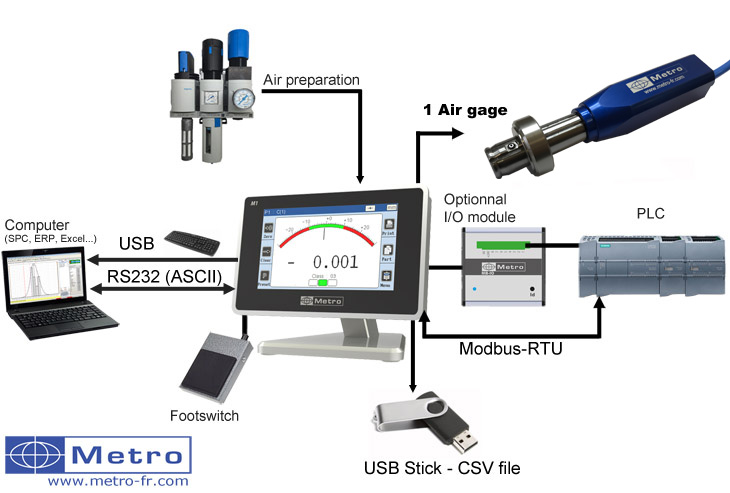

This display has different communication means, USB and RS232. This allows to drive the device and to read the measurements from a computer or a PLC.

Its case, machined in a solid aluminum block offers to the M3 an unequalled robustness, even used in severe industrial environment (cutting oil etc...)

- 2 measurement configurations (2 dimensions)

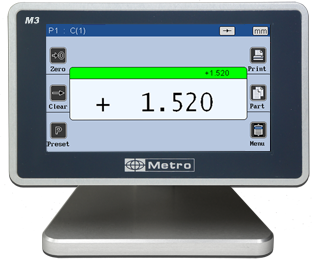

- Different display modes with 1 or 2 dimensions per screen, with or without tolerances.

- Static and dynamic measurement (Min, Max, Max-Min, Average, Median)

- Control limits

- Sorting by classes (up to 16 classes)

- Connection of an optional box with 8 optocoupled inputs/outputs (MB-IO)

- Absolute or relative measurements

- Modbus RTU or ASCII communication

- USB keyboard function when the M3 is connected to a PC

- Automatic change of measurement configuration by buffer detection during use

- Integrated cone calculation

- Optional temperature monitoring and/or compensation

- Safe and easy to use

- Can be configured with a QR code scan, allowing a buffer change in a few seconds

- Very short stabilization time of the measurement

Many functions and operating modes can be defined:

- Nominal dimension, tolerance limits, control limits, standard dimension (reference part).

- Choice between 2 measurement configurations (2 dimensions)

- Calculation formula (C1, C2, -C1, -C2, C1+C2, C1-C2, -C1+C2, -C1-C2, 3-point diameter)

- Calibration

- Static or dynamic measurements (Min, Max, Max-Min, Average and Median)

- Relative or absolute mode

- Single or multi-range display mode (2 bar graphs) with or without tolerances

- Sorting by classes, up to 16 classes

- Locking of some functions with masking of buttons for a maximum simplified user interface

- Display resolution (2 to 5 decimal places)

- Metric (mm or µm) or inch measurements

- M-Bus connector to connect a box with 8 optocoupled inputs/outputs (good part, bad part, calibration etc...)

- Automatic dimension change by detection of sensor movements

- Choice of language for the user interface

The M3 is equipped with a mini-USB connector with 2 functions

1. Power supply via a supplied wall transformer.

2. Measurement transmission: When the M3 is connected in USB to a PC, it is detected as a keyboard with the standard drivers of your operating system (Windows, MacOS, Linux...). When you transfer measurements from the M3, they appear on your computer screen as if they had been entered on the keyboard. No need to install any specific driver or software.

Advantages of this feature:

- No risk of error when entering values

- Saves time

- Works everywhere on all software: Excel, SAP, Word....

- No need for a driver, interface software or computer knowledge: you just plug in the display and you can work

A serial interface RS 232 allows the transmission of measurements as well as the remote control of all the functions of the M3 thanks to ASCII commands or the MODBUS-RTU protocol

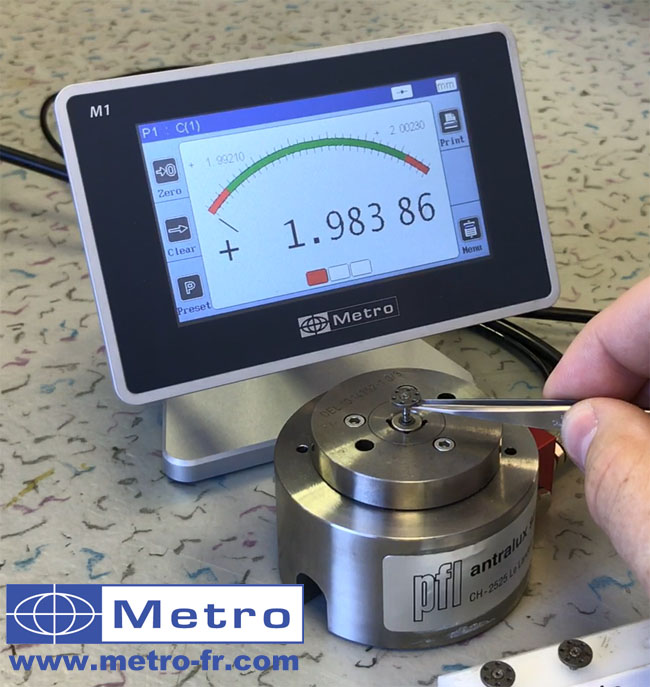

Measurement of an 2mm external diameter on a diesel injector part, using an high resolution air ring directly connected on the M1 display.

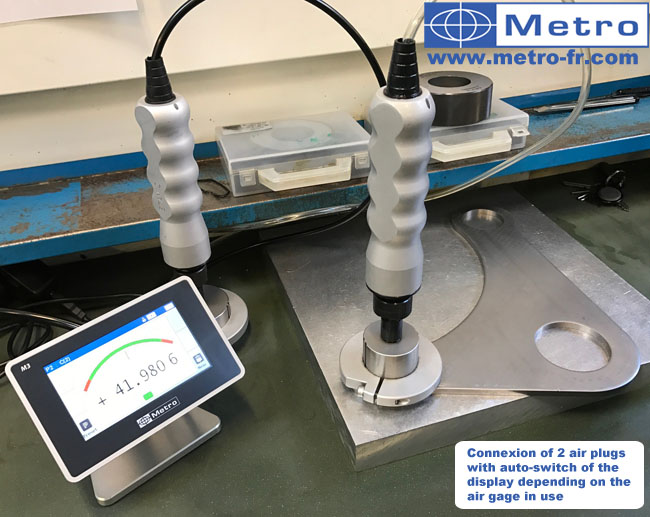

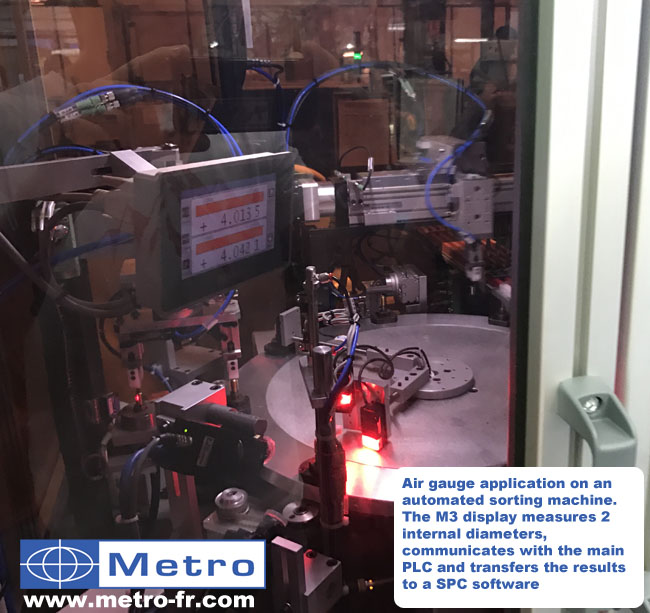

2 needle indicators have been replaced by 1 m3 display. Depending on the air plug in use, the display shows the current measurement. It alows to save space on the working area and to prevent measurement error by a very clear green/red indication

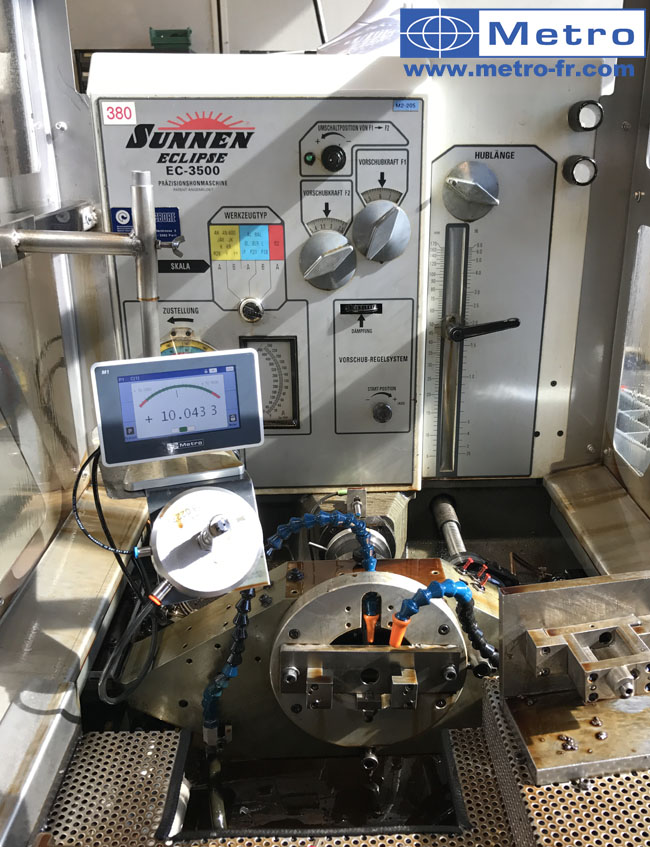

Measurement of internal diameter on a Honing machine, oily environment. The air flow can "clean" the part by removing the oil at the measuring point.

Air gauge application on an automated sorting machine. The M3 display measures 2 internal diameters, communicates with the main PLC and transfers the results to a SPC software

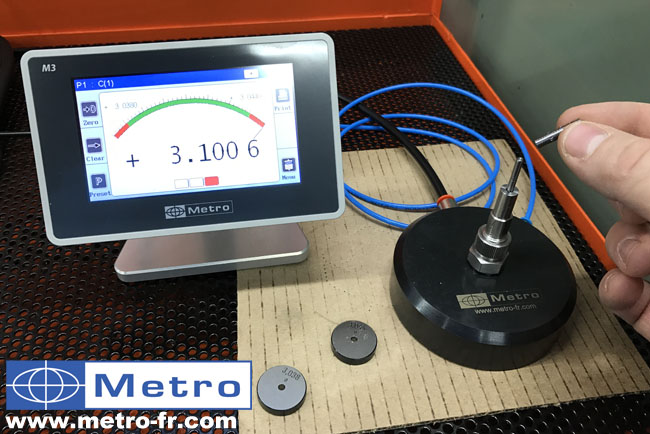

Measurement of a 3mm internal diameter of a precision automotive part.

The M3 AG must be used with a precision pressure regulator. It is recommended to use the regulator supplied by Metro to ensure the best possible measurements!

We also propose a version with air saving functions.

This robust and ergonomic button is made on a machined aluminum base.

It advantageously replaces the pedal when it is used on a table.

Compatible with all Metro products: Displays and multiplexers.

Module with one relay output - to pilot air economy system or air gage probe output.

It is fitted with a M12 connector

To be used with the cable 45186-1.5

The MB-IO M-Bus box has 8 optocoupled inputs/outputs for additional functionality, e.g. output of good or bad parts, calibration input etc. The M-Bus units are presented in an aluminum profile that can be mounted on a standard DIN rail. More details on this page: M-BUS

Air preparation unit with solenoid valve for air gages with air saving function. This controller can be controlled with the MB-RO module.

Used with Metro M400, M1 or M3 displays, this regulator reduces the pressure (the pressure is divided by approximately 10) automatically after an adjustable period of time without use.

This allows significant savings in electricity, without completely cutting off the air, which would deteriorate the measurement due to the temperature variation.

This sturdy pedal can be configured in different ways: calibration, measurement transmission, start of dynamic measurement etc...

Allows the connection of compatible M-Bus boxes to an M3 display for Heidenhain probes or Air gages.

The M3 for inductives probes require a cable ref 81210-2

This cable is used to connect the M2/M3 to a computer.

This cable is used to connect the M2/M3 to a Metro Mux multiplexer

The MB-TP module is used to read a type K thermocouple or a PT100 probe and use it on a Metro display to create an alarm on a temperature variation or to perform temperature compensation of the measurement.